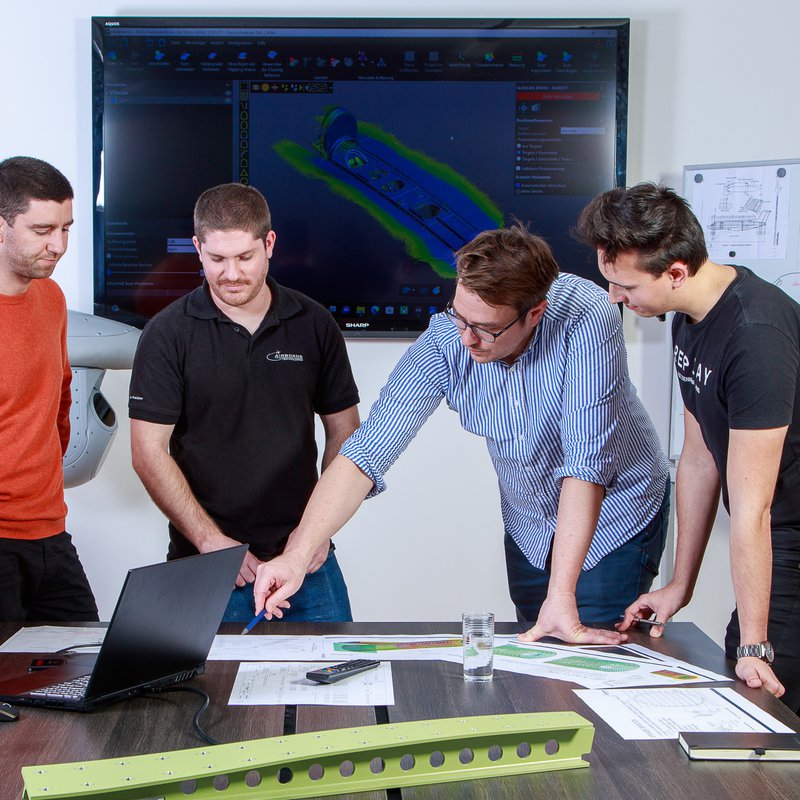

Client Consultation

With our multi-discipline staff of engineers, fabricators, and technicians, we have the experience and know-how to assist our clients throughout the process of any special aircraft integration & modification project.

With a track record of developing more than 100 STCs and conducting over 300 aircraft changes, our clients benefit tenfold from our knowledge and expertise.

When it comes to client consultation, we here at Airborne Technologies will manage everything from initial requirements development, on-site surveys, live demos, feasibility studies and more.

Mechanical & System Design

Airborne Technologies maintains a full suite of preliminary design methods for the sizing and assessment of new aircraft configurations. Our innovative design methods incorporate our best practice methods to quickly and efficiently identify an optimum configuration.

Our in-house design capabilities include software designing & development, mechanical designing, and system designing. Along with this, we manage every step of the design process from problem identification to critical design review.

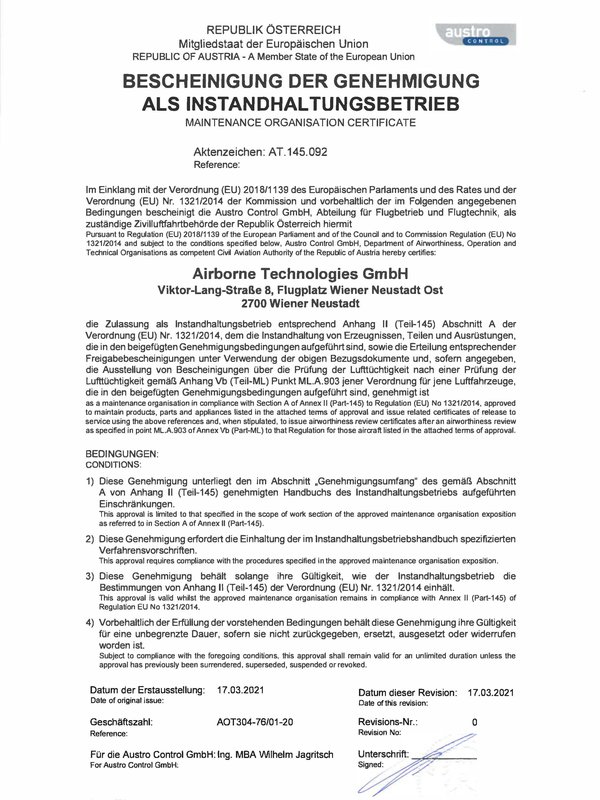

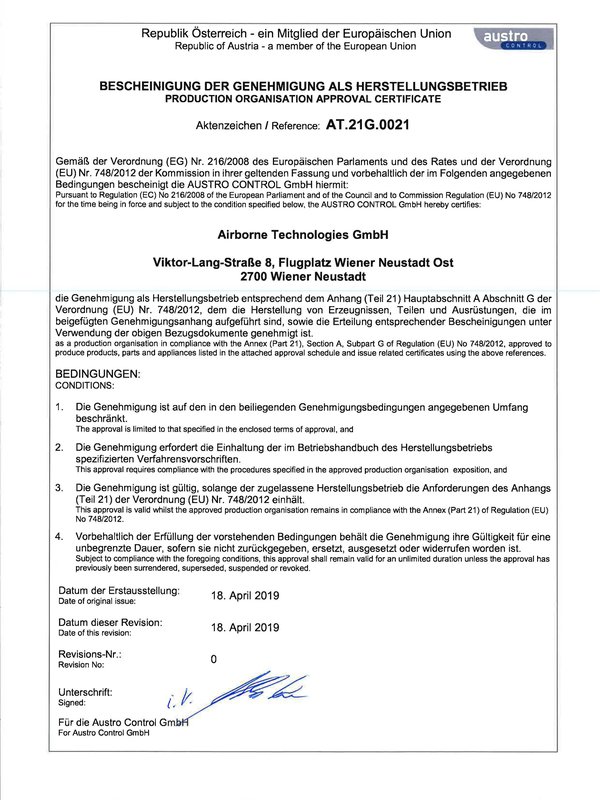

Certification Process

Like an aircraft manufacturer (OEM´s) and to save our clients time and money, Airborne Technologies is approved by EASA (Part 21 – Design and Production Organisation, Part 145 Maintenance Organisation) to certify an airframe modification from nose-to-tail without approvals by the OEM´s.

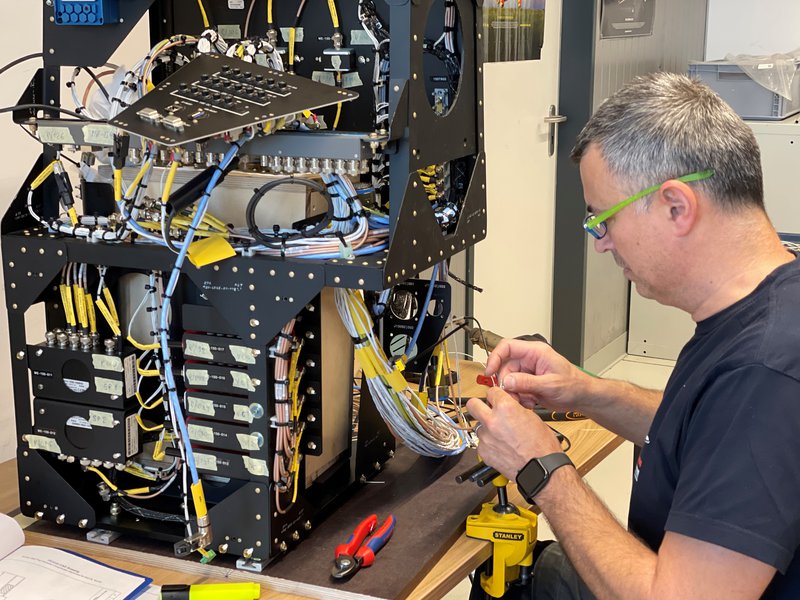

Manufacturing

The interdisciplinary know-how of our employees is the basis for the extensive scope of work our EASA approval covers. Since all the production and manufacturing of sub & secondary components are accomplished in-house, the customer benefits from the efficiency of having all parts produced under one roof.

Our in-house production and manufacturing capabilities include:

- Carbon Fibre Parts & Milling

- Electrical Components Production

- Radome Production

- Cable Harness Production

- Metal Components Production

TESTING & QUALITY ASSURANCE

With our in-house test center, fully equipped test aircraft, and certified test pilots, we can assist our clients with specific mission equipment testing and demonstration flights.

Along with our testing capabilities, our quality management includes everything we do to ensure every project specification is met and reasonably priced.

Our testing & QM functions include:

- Flight Testing (in-house)

- Tensile Tests

- Ground Tests

- Quality Assurance

Export management

With our trained staff with decades of experience in managing U.S. ITAR and European export licence procedures and processes, we take the stress off our clients so they don't have to navigate the ever increasing export compliance burdens.

Installation

Installation in our facility or yours - it doesn’t matter. We can easily accomplish all steps of any aircraft modification & installation project in both locations. Additionally, we can complete all system and flight testing for EASA compliance reports at your facilities.

Training

If requested, we provide training as part of any integration or modification project. We'll ensure aircraft maintenance personnel and flight crews are fully trained and qualified to operate their new systems and components with maximum proficiency.

With our comprehensive and ongoing training programs, we can offer a hands-on learning experience either at our training center or at the client's location.

Support & maintenance

As a certified Maintenance Organisation we maintain, repair, modify and upgrade components already in service.

We provide all your parts and ground support needs. We stock an extensive inventory of components and parts for exchange or outright purchase, and we maintain a large inventory of tooling and test equipment.